The Problem with Conventional Adhesives

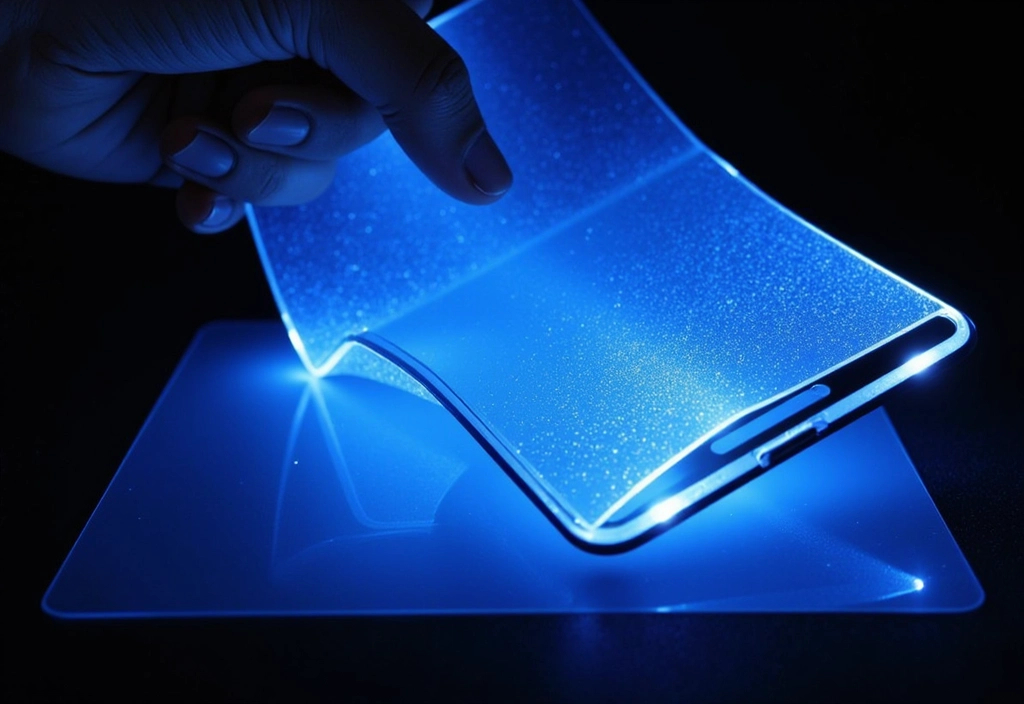

Foldable displays continue to grow in popularity, but traditional adhesives haven’t kept pace. These adhesives stick too well and leave behind residue when removed. Even worse, they don’t break down easily, often turning into microplastics.

This creates major problems for recycling and reuse, especially in high-value electronics where manufacturers aim to recover expensive display layers.

A Smarter, Cleaner Adhesive

Researchers have now developed a new adhesive that solves these issues. It contains more than 60% bio-based ingredients and supports both clean removal and chemical recycling.

More importantly, it performs just as well as traditional acrylic adhesives. It provides strong adhesion, high optical clarity, and flexibility across a wide temperature range.

How It Works

The new adhesive uses lipoic acid ethyl ester (LpEt), a natural compound, as a core ingredient. Scientists cure the adhesive with visible light, which is safer and more energy-efficient than UV curing.

To enable clean removal, they added a special UV-sensitive monomer. When exposed to UV light, the adhesive’s internal structure changes. This extra crosslinking makes the adhesive less sticky, so users can peel it off without residue.

Proven Performance in Real-World Conditions

The team tested the adhesive under different conditions and temperatures. All versions remained flexible and transparent. Even at low temperatures, the adhesive stayed strong.

After UV exposure, the adhesive lost over 85% of its bonding strength. This allowed researchers to cleanly separate it from delicate substrates like glass and PET film—without damaging the surface or leaving sticky remains.

Designed for Sustainability

Unlike most adhesives, this one doesn’t just come off cleanly. It also breaks down into small, safe molecules when treated with mild, environmentally friendly chemicals like NAC or DTT.

In tests, researchers observed complete degradation with no sticky residue. They even recovered the original monomers using gentle chemical treatments. This shows the adhesive can re-enter the manufacturing cycle, making it part of a closed-loop system.

Customizable for Different Applications

To make the adhesive more versatile, researchers tested different combinations of acrylate monomers. For instance, they added methyl methacrylate for added strength or butyl acrylate for extra flexibility.

All these formulations still allowed clean removal and full degradation. This means manufacturers can adjust the adhesive for specific product needs—without sacrificing sustainability.

Why This Innovation Matters

This adhesive offers something rare: high performance and real sustainability. It sticks well, peels cleanly, degrades safely, and can be reused.

Even better, the ingredients are already mass-produced. That makes it easy for display manufacturers to adopt this system without changing their entire production process. It’s a practical solution with global potential.

The Road Ahead for Greener Electronics

As the electronics industry moves toward sustainability, adhesives like this one could become a key part of the solution. They support recycling, reduce waste, and make it easier to recover expensive materials.

With this innovation, foldable displays—and many other electronic devices—can become cleaner, safer, and easier to reuse. It’s a smart step forward for both the planet and the tech industry.

Check out the cool NewsWade YouTube video about this article!

Article derived from: Y. Park, S. Lim, M. S. Kwon, Cleanly Removable and Degradable Bio-Based Adhesive for Flexible Displays. Adv. Mater. 2025, 2420538. https://doi.org/10.1002/adma.202420538