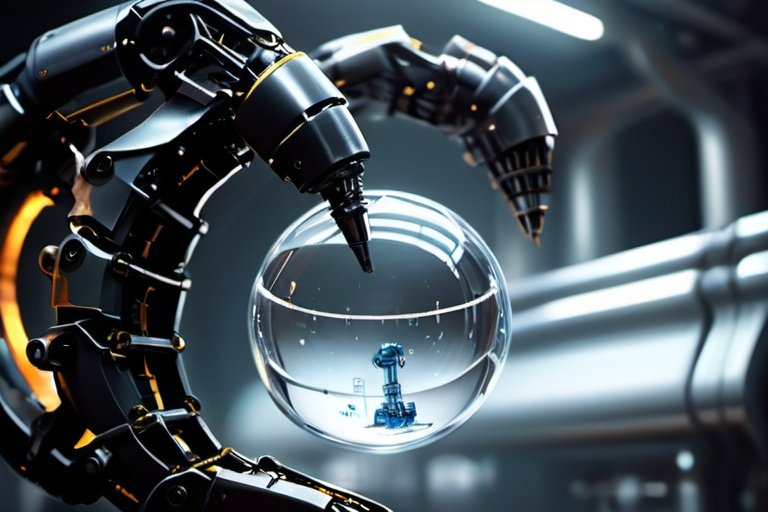

In the rapidly evolving world of robotics, one of the most critical challenges lies in designing grippers that can perform precision tasks efficiently. A groundbreaking study by Imad A. Kheioon, Raheem Al-Sabur, and Abdel-Nasser Sharkawy has introduced an innovative approach to robotic gripper design, incorporating a cam mechanism and an adaptive neuro-fuzzy inference system (ANFIS). Here, we explore how this technology is shaping the future of robotics and automation.

A New Era in Robotic Gripper Design

Traditional robotic grippers often struggle to balance strength, precision, and adaptability. This study enhances the conventional design by integrating a cam mechanism to improve gripping strength and motion control. The researchers employed MATLAB Simulink to model the system, achieving impressive results that position their design ahead of existing technologies.

The Power of ANFIS-PID Control

At the core of this innovation is the ANFIS-PID controller, a hybrid system combining the adaptability of fuzzy logic with the learning capabilities of neural networks. By using three methods—grid partitioning (genfis1), subtractive clustering (genfis2), and fuzzy C-means clustering (genfis3)—the researchers tuned the proportional, integral, and derivative (PID) parameters with unparalleled precision. Key performance improvements include:

- Rise Time Reduction: Improved by 50-51% compared to traditional controllers.

- Steady-State Error: Reduced by 75-95% over traditional PID and Fuzzy-PID controllers.

- Robustness Against Disturbances: The controller demonstrated high resilience to internal and external disturbances.

Position and Force Control: A Game-Changer

The study’s innovative gripper design supports:

- Position Control: The ANFIS-PID controller precisely managed displacements ranging from 0.05 cm to 1.5 cm, crucial for delicate tasks like assembling electronic components.

- Force Control: Tests showed superior gripping performance across scenarios, from applying consistent force to adapting to sudden changes.

Why This Matters

The potential applications of this technology span industries, including manufacturing, healthcare, and logistics. With enhanced precision and adaptability, robotic grippers could revolutionize tasks such as:

- Handling delicate materials.

- Performing surgeries.

- Automating assembly lines with diverse object shapes and sizes.

Comparison with Existing Technologies

Compared to traditional PID and Fuzzy-PID controllers, the ANFIS-PID controller excels in:

- Accuracy: Handles nonlinearities with greater precision.

- Stability: Maintains performance despite dynamic disturbances.

- Flexibility: Adapts seamlessly to varying tasks and conditions.

Future Implications

The study’s authors emphasize that while their results are promising, future work could explore:

- Testing the design with complex input functions like ramp or random signals.

- Comparing its performance against robust controllers like H-Infinity.

- Implementing the design in real-world experiments.

Conclusion

This innovative robotic gripper design sets a new benchmark in automation technology. By combining mechanical ingenuity with advanced control algorithms, it paves the way for more versatile, precise, and efficient robots. As industries increasingly rely on automation, such advancements will play a pivotal role in shaping the future.

Article derived from: Kheioon, I. A., Al-Sabur, R., & Sharkawy, A.-N. (2025). Design and Modeling of an Intelligent Robotic Gripper Using a Cam Mechanism with Position and Force Control Using an Adaptive Neuro-Fuzzy Computing Technique. Automation, 6(1), 4. https://doi.org/10.3390/automation6010004

Check out the cool NewsWade YouTube video about this article!