In a groundbreaking move, the Defense Advanced Research Projects Agency (DARPA) is taking its Novel Orbital and Moon Manufacturing, Materials, and Mass-efficient Design (NOM4D) program to new heights. The agency has recently announced plans to transition from laboratory experiments to small-scale orbital demonstrations, marking a significant leap in space manufacturing technology1.

The Vision of NOM4D

NOM4D, pronounced “nomad,” aims to overcome traditional limitations in space infrastructure construction. Launched in 2022, the program’s primary goal is to develop foundational materials, processes, and designs for in-space manufacturing of large, precise, and resilient defense systems1.

Instead of relying on pre-assembled structures launched from Earth, NOM4D proposes a paradigm shift:

- Transporting lightweight raw materials to space

- Assembling structures in orbit

- Creating larger and more mass-efficient structures than ever before

From Lab to Orbit

DARPA’s decision to move NOM4D into orbital testing comes after rapid technical progress in earlier phases. Two university-led research teams will spearhead the program’s third phase1:

- California Institute of Technology (Caltech)

- University of Illinois Urbana-Champaign (UIUC)

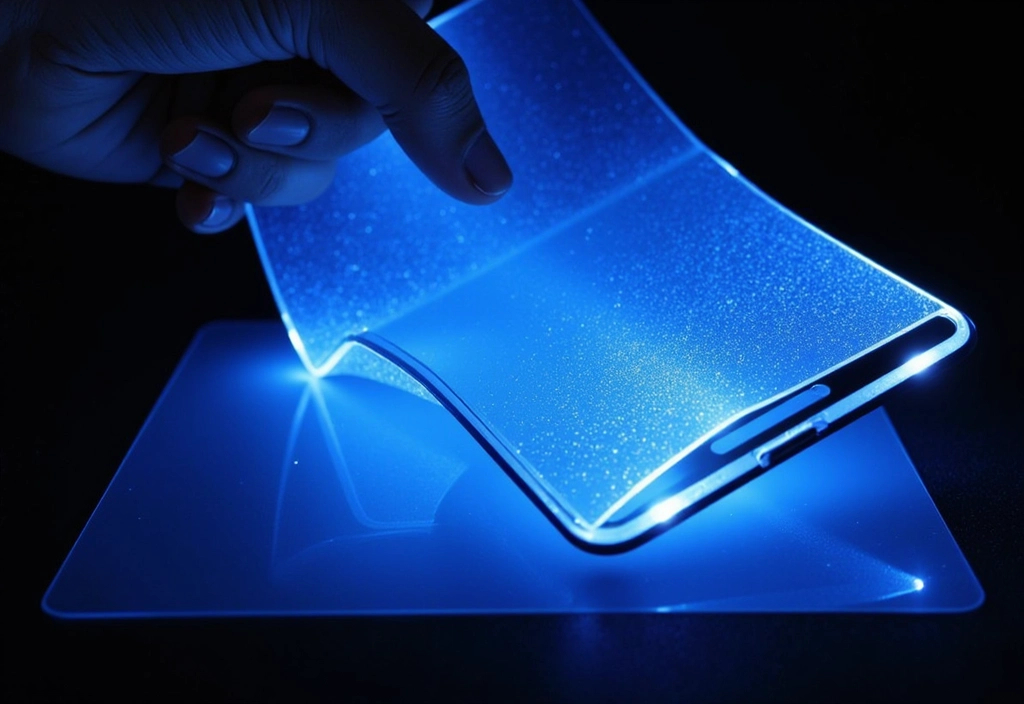

The UIUC team will demonstrate a special frontal polymerization process, combining and hardening carbon fiber sleeves with liquid monomers in space without significant heat sources. This technology could enable unlimited expansion of structures, limited only by available materials1.

Potential Applications

The innovations from NOM4D could revolutionize space infrastructure in the coming decades. Potential applications include:

- Larger, more complex orbital laboratories

- Massive radio antennas for communications systems

- Expansive solar arrays for power generation

- Refueling stations for future spacecraft

One ambitious long-term goal is the construction of 100-meter-wide space-based antennas. These structures could dramatically enhance situational awareness in the challenging cislunar region between Earth and the Moon1.

Implications for Defense and Space Exploration

NOM4D’s success could have far-reaching implications for both defense and space exploration:

- Enhanced Space Situational Awareness: Larger structures could improve monitoring of activities in cislunar space and beyond2.

- Mass Efficiency: By manufacturing in space, structures can be optimized for the low-gravity environment, eliminating the need to withstand launch forces3.

- Scalability: The ability to construct large structures in orbit could pave the way for more ambitious space projects and missions.

The Road Ahead

As NOM4D moves into its orbital testing phase, the space industry watches with anticipation. If successful, this program could usher in a new era of space manufacturing and construction, opening up possibilities that were once confined to the realm of science fiction.

DARPA’s NOM4D mission represents a bold step towards realizing the full potential of human presence in space. By pushing the boundaries of what’s possible in orbital manufacturing, we may soon see a future where massive space structures are not just feasible but commonplace.

Check out the cool NewsWade YouTube Video about this article!

Article derived from:

1. Hanks, M. (2025, February 11). DARPA Program Plans to Build Massive Structures in Orbit with Paradigm-Shifting Technology. The Debrief. https://thedebrief.org/darpa-program-plans-to-build-massive-structures-in-orbit-with-paradigm-shifting-technology/

2. CHIPS Articles: Manufacturing experiment will move from the lab to in-orbit evaluation. (n.d.). https://www.doncio.navy.mil/Chips/ArticleDetails.aspx?ID=18143

3. DARPA’s NOM4D program: re-inventing Manufacturing in space. (2021, February 8). Secret Projects Forum. https://www.secretprojects.co.uk/threads/darpas-nom4d-program-re-inventing-manufacturing-in-space.36498/