Introduction

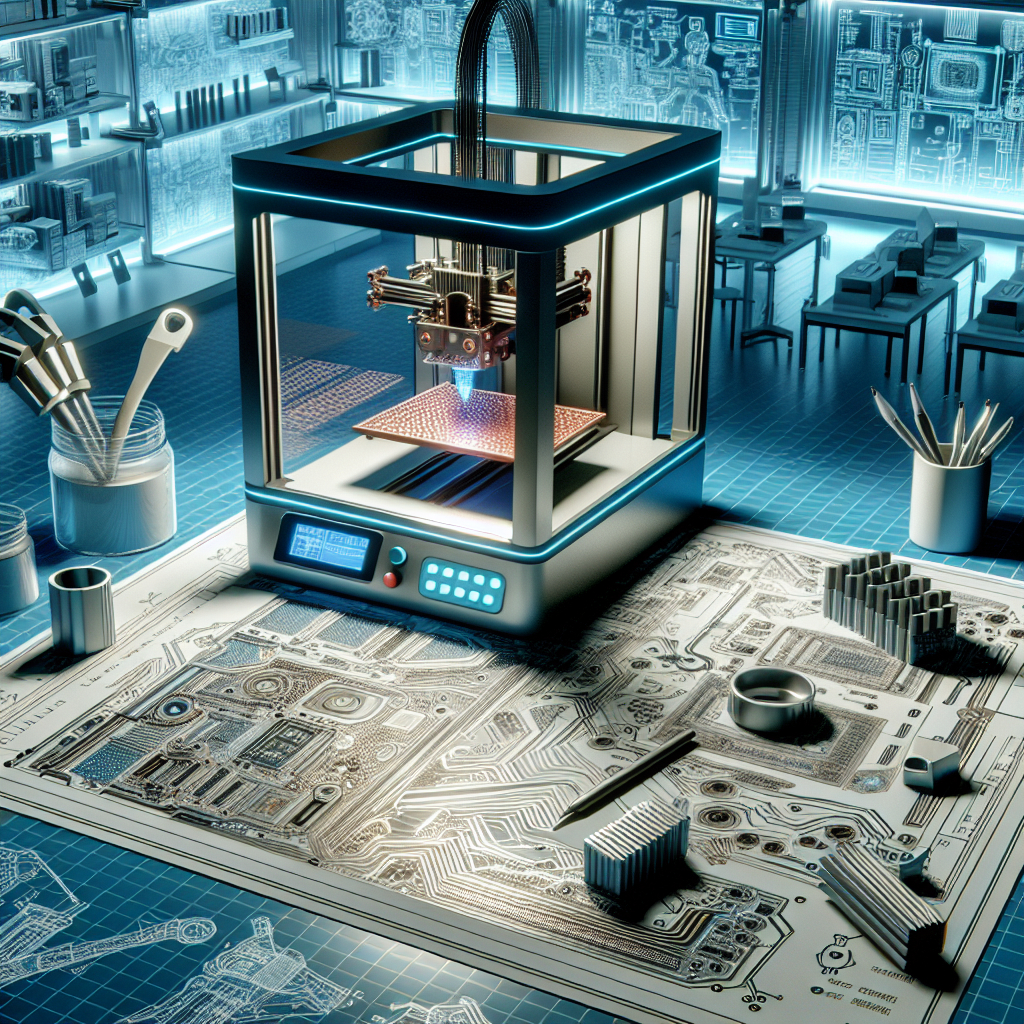

3D printing has come a long way since its inception, evolving from a niche technology to a versatile manufacturing tool. Now, researchers at MIT have taken 3D printing to new heights by successfully creating functional electronic components. This breakthrough could revolutionize the way we produce electronics, making the process more accessible, cost-effective, and environmentally friendly.

MIT’s Groundbreaking Achievement

MIT researchers have achieved a significant milestone in the field of electronics manufacturing. They have successfully created functional logic gates using 3D printing technology, without relying on traditional semiconductor materials. This achievement marks a pivotal shift towards innovative and simplified manufacturing methods in the electronics industry.

What Are Logic Gates?

Logic gates are fundamental building blocks of digital circuits. They perform basic logical operations and are essential for creating more complex electronic systems. Traditionally, these components are manufactured using semiconductor materials in specialized fabrication facilities.

The Significance of MIT’s Breakthrough

By creating logic gates using 3D printing, MIT researchers have demonstrated that it’s possible to produce electronic components without the need for complex and costly semiconductor fabrication processes. This development has the potential to democratize electronics manufacturing, making it more accessible to smaller businesses and individual inventors.

The Technology Behind 3D Printed Electronics

The key to MIT’s success lies in the innovative materials and processes they’ve developed:

- Biodegradable Polymer: The team created a unique biodegradable polymer infused with copper particles. This material can conduct electricity, making it suitable for electronic applications.

- 3D Printing Process: Using advanced 3D printing techniques, the researchers can directly fabricate electronic components with this conductive polymer.

- Bypassing Traditional Methods: This approach eliminates the need for extensive semiconductor processing, simplifying the manufacturing process significantly.

How It Works

- The conductive polymer is prepared and loaded into the 3D printer.

- The printer then precisely deposits the material layer by layer, following a digital design.

- As the material is deposited, it forms the structure of the electronic component, including the necessary conductive pathways.

- Once printed, the component is ready for use or further integration into larger circuits.

Advantages of 3D Printed Electronics

This innovative approach to electronics manufacturing offers several benefits:

- Cost-Effective: By eliminating the need for expensive semiconductor fabrication facilities, the cost of producing electronic components could be significantly reduced.

- Environmentally Friendly: The use of biodegradable materials aligns with sustainability efforts, potentially reducing electronic waste.

- Accessibility: This technology could enable local production of electronics, allowing communities to create their own devices without relying on large manufacturing plants.

- Rapid Prototyping: 3D printing allows for quick iterations and modifications, speeding up the development process for new electronic devices.

- Customization: The flexibility of 3D printing enables the creation of custom-designed components tailored to specific needs.

Potential Applications

The implications of this technology are far-reaching and could impact various sectors:

- Consumer Electronics: Customized gadgets and devices could be produced more easily and at lower costs.

- Medical Devices: Personalized medical electronics, such as hearing aids or prosthetics, could be manufactured on-demand.

- Internet of Things (IoT): The production of sensors and small electronic devices for IoT applications could become more accessible and affordable.

- Education: Schools and universities could use this technology to teach electronics manufacturing, giving students hands-on experience.

- Remote Areas: Communities in remote locations could produce necessary electronic components locally, reducing dependence on supply chains.

Challenges and Future Developments

While this breakthrough is promising, there are still challenges to overcome:

- Performance: Currently, 3D printed electronics may not match the performance of traditional semiconductor-based components in all applications.

- Scalability: The technology needs to be scaled up for mass production while maintaining quality and reliability.

- Material Development: Further research is needed to develop a wider range of printable electronic materials with diverse properties.

- Design Tools: New software and design tools may be required to fully leverage the capabilities of 3D printed electronics.

Future Outlook

Researchers at MIT are optimistic about the future of this technology. As they continue to refine the process and improve functionality, we can expect to see significant developments in the coming years. While there’s no specific timeline for commercial availability, the potential impact on the electronics industry is substantial.

Conclusion

The breakthrough in 3D printing of electronic components by MIT researchers represents a significant step towards more accessible, sustainable, and innovative electronics manufacturing. As this technology continues to develop, it has the potential to transform the way we design, produce, and use electronic devices.

This advancement not only showcases the evolving capabilities of 3D printing but also highlights the potential for more inclusive and environmentally friendly practices in the electronics industry. As we look to the future, 3D printed electronics could play a crucial role in democratizing technology and fostering innovation across various sectors.

Learn more about 3D printing technologies

Explore MIT’s research in advanced manufacturing

If you want to watch this on youtube: https://youtu.be/XyUz7UDK90Y

Article derived from: MIT News. (2024, October 15). MIT team takes a major step toward fully 3D-printed active electronics. Massachusetts Institute of Technology. https://news.mit.edu/2024/mit-team-takes-major-step-toward-fully-3d-printed-active-electronics-1015

Disclaimer: This content was simplified and condensed using AI technology to enhance readability and brevity.