In the ever-evolving world of manufacturing, co-extrusion technology has emerged as a game-changer, particularly in the plastic industry. This innovative process is transforming how we create multi-layered plastic products, offering unprecedented benefits in terms of functionality, aesthetics, and sustainability. Let’s dive into the world of co-extrusion and explore how it’s reshaping the future of plastic manufacturing.

What is Co-Extrusion?

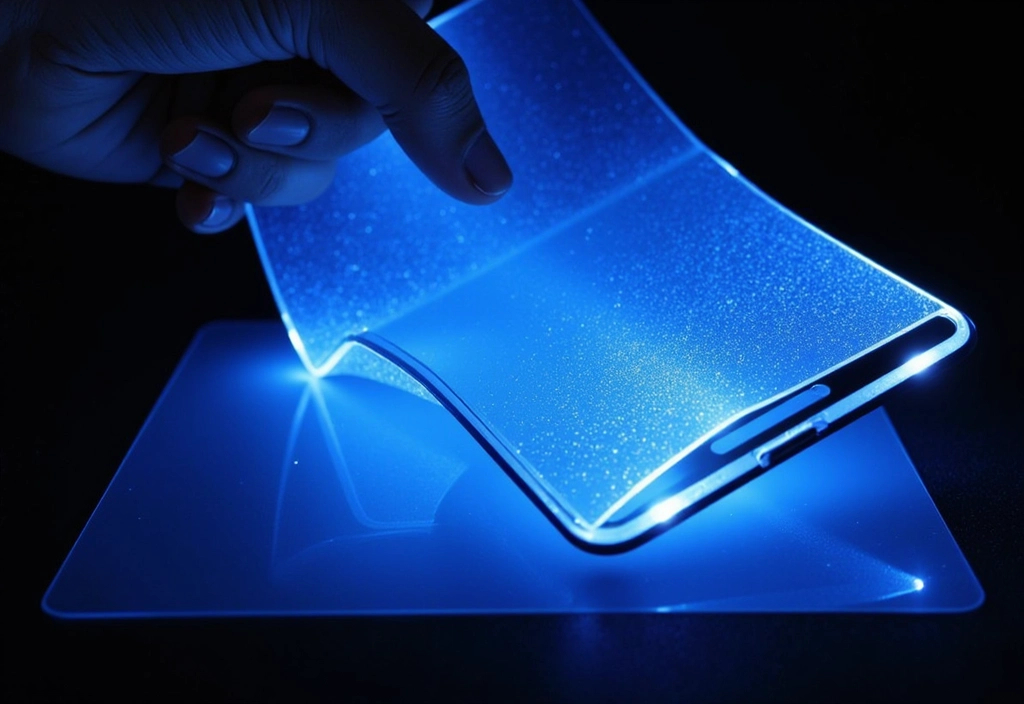

Co-extrusion is an advanced manufacturing technique that allows multiple materials to be extruded simultaneously through a single die. This process results in a final product with multiple layers, each contributing unique properties to the whole. Unlike traditional extrusion methods, co-extrusion enables manufacturers to combine different plastics seamlessly, creating products with enhanced performance characteristics.

The Advantages of Co-Extrusion

Unparalleled Material Optimization

One of the most significant benefits of co-extrusion is the ability to optimize material usage. Manufacturers can strategically place high-performance materials where they’re most needed while using more cost-effective options in less critical areas. This not only reduces overall production costs but also ensures that each part of the product is designed for maximum efficiency.

Enhanced Durability and Functionality

Co-extruded products often exhibit superior durability compared to their single-material counterparts. By combining materials with complementary properties, manufacturers can create products that are stronger, more weather-resistant, and longer-lasting. For instance, a co-extruded window profile might feature a UV-resistant outer layer for longevity and an insulating inner layer for energy efficiency.

Aesthetic Appeal

Co-extrusion opens up a world of design possibilities. Manufacturers can incorporate decorative layers or color variations without compromising on structural integrity. This versatility allows for the creation of visually striking products that stand out in the market.

Sustainability in Focus

In an era where environmental concerns are paramount, co-extrusion offers a path to more sustainable manufacturing. The technology allows for the incorporation of recycled materials into non-visible layers, reducing the reliance on virgin plastics without sacrificing product quality or appearance.

Applications Across Industries

The versatility of co-extrusion technology has led to its adoption across various industries:

- Construction: Window and door profiles with enhanced insulation and weather resistance

- Automotive: Lightweight, durable components with specific performance characteristics

- Lighting: LED diffusers that combine optical clarity with structural strength

- Packaging: Multi-layer films with improved barrier properties

- Consumer Goods: Products with both aesthetic appeal and functional benefits

The Future of Plastic Manufacturing

As we look to the future, co-extrusion is poised to play an increasingly important role in plastic manufacturing. Its ability to create complex, multi-functional products while addressing sustainability concerns makes it an attractive option for manufacturers looking to innovate and stay competitive.

Conclusion

Co-extrusion technology represents a significant leap forward in plastic manufacturing. By enabling the creation of multi-layered products with optimized properties, it offers solutions to many of the challenges faced by modern industries. From enhancing product performance to supporting sustainability initiatives, co-extrusion is truly revolutionizing how we think about and produce plastic goods.

As this technology continues to evolve, we can expect to see even more innovative applications and advancements in the field of plastic manufacturing. The future of co-extrusion is bright, promising a new era of efficient, sustainable, and high-performance plastic products.

Check out the cool NewsWade YouTube video about this article.

Article derived from: Admin. (2025, January 13). Co-Extrusion revolutionizing plastic extrusion technology. Seiki. https://xtruline.com/co-extrusion-revolutionizing-plastic-extrusion-technology/