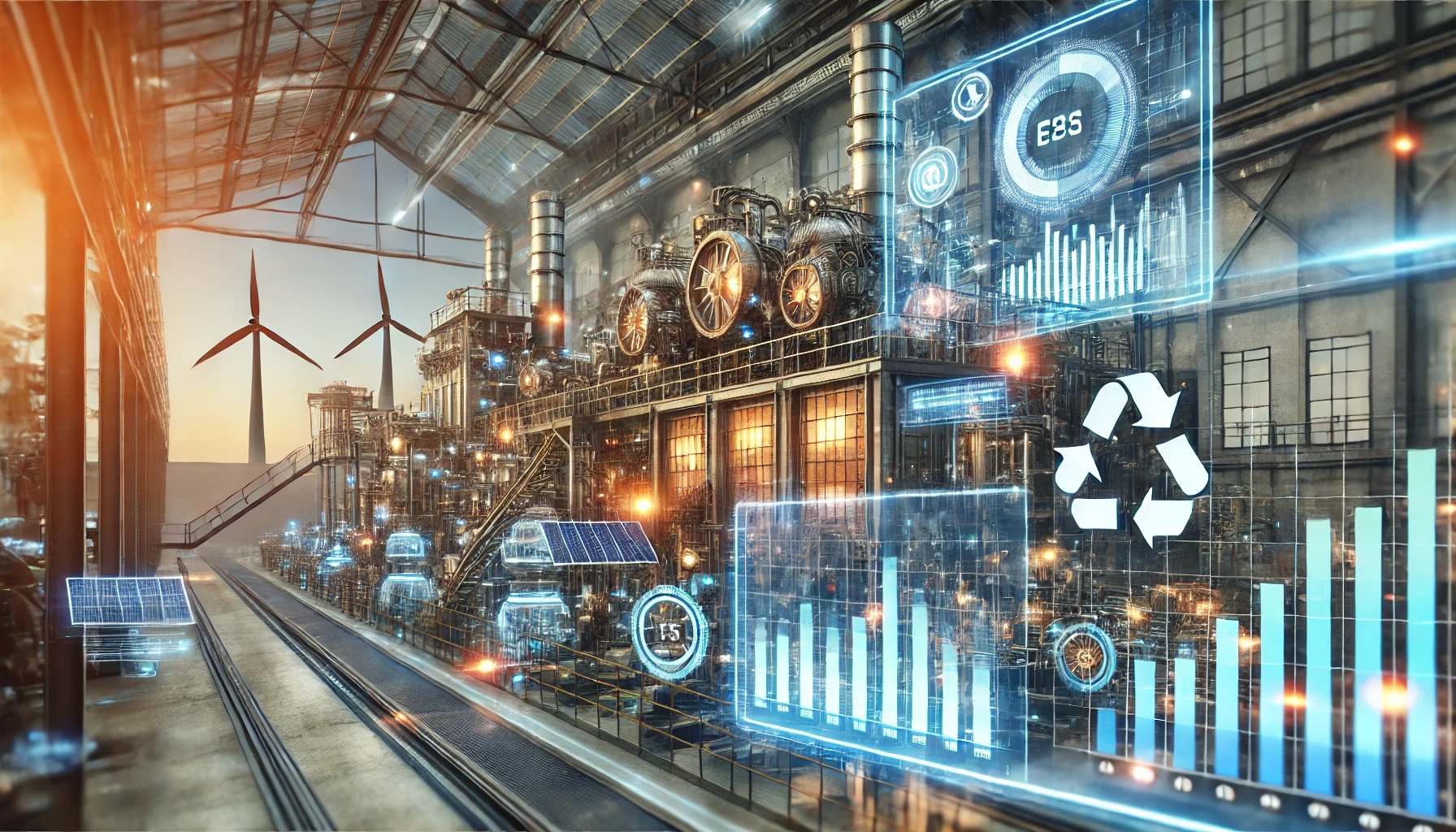

In an era where decarbonization and sustainability are redefining the global energy landscape, optimizing power consumption in industrial enterprises is more critical than ever. A recent study explores innovative algorithms and methods to analyze and manage power consumption behavior in industries, offering a roadmap to greater efficiency, lower costs, and reduced environmental impact.

The Challenge of Power Consumption in Industrial Enterprises

Industrial operations are power-intensive, and their energy demands often fluctuate due to the nature of production processes. Factors such as seasonal variations, production schedules, and unexpected technical failures make power management a complex task. Traditional, manual approaches to power consumption management are proving inadequate in a world increasingly driven by automation and digitalization.

The integration of renewable energy sources, such as solar and wind, further complicates this equation due to their inherent unpredictability. Industries need advanced, automated systems to monitor, analyze, and optimize their power consumption patterns, ensuring production continuity and efficiency.

A Smarter Approach to Power Management

This study introduces a groundbreaking algorithm designed to tackle these challenges head-on. It focuses on analyzing the specific characteristics of industrial processes, incorporating:

- Non-Stationary Conditions: The algorithm accounts for variations in power consumption caused by dynamic production conditions.

- Random Factors: Internal and external random factors influencing power use are modeled for better predictability.

- Level-Crossings of Random Processes: This mathematical approach improves data reliability, enabling better decision-making for power optimization.

The results show that by leveraging these methods, industries can improve power consumption efficiency by 15–20% while meeting production goals.

Key Features of the Algorithm

The study highlights several practical features of the developed algorithm:

- Real-Time Monitoring: Automated systems can now track deviations in power use, ensuring quick responses to maintain production efficiency.

- Flexibility in Production Speed: The algorithm suggests adjustments to production speed based on available power, ensuring deadlines are met without compromising quality.

- Probabilistic Forecasting: Advanced modeling predicts fluctuations in power consumption, allowing industries to plan better and minimize risks.

Benefits for Industrial Enterprises

Adopting these methods offers significant advantages:

- Reduced Costs: Intelligent power management minimizes wastage, translating into lower electricity bills.

- Enhanced Sustainability: Optimizing power use aligns with decarbonization goals, reducing the carbon footprint of industrial operations.

- Improved Reliability: Automated systems reduce dependency on human intervention, mitigating errors and ensuring seamless operations.

- Scalability: These methods can be customized to suit diverse industries, from chemical plants to mechanical engineering firms.

Applications and Future Potential

Industries worldwide are already benefiting from innovations like “demand response” technology, where enterprises reduce power use during peak hours for financial incentives. The study’s findings take this a step further by integrating these capabilities into fully automated systems.

Moreover, the research paves the way for industries to build resilience against power disruptions. By investing in on-site distributed generation facilities, such as solar or wind power, enterprises can safeguard production even during grid failures.

A Step Toward Smarter, Greener Factories

The digitalization of the energy sector is no longer a choice—it’s a necessity. By embracing algorithms and automated systems for power consumption management, industrial enterprises can not only cut costs but also lead the charge toward a more sustainable future.

With further refinement, these methods could revolutionize industrial operations, setting new benchmarks for energy efficiency, reliability, and environmental stewardship.

Conclusion

Power consumption is a vital component of industrial operations, and managing it efficiently is essential for cost savings, sustainability, and reliability. The methods and algorithms developed in this study offer a clear path forward for industries to optimize their energy use without compromising productivity.

As industries continue to digitize and automate, these advancements in power management will play a pivotal role in shaping smarter, greener factories of the future.

Article derived from: Ilyushin, P., Papkov, B., Kulikov, A., & Suslov, K. (2025). Algorithm and Methods for Analyzing Power Consumption Behavior of Industrial Enterprises Considering Process Characteristics. Algorithms, 18(1), 49. https://doi.org/10.3390/a18010049

Check out the cool NewsWade YouTube video about this article!