What if the same material holding your car together could also power it? That’s the revolutionary idea behind carbon fiber structural batteries, a breakthrough technology that combines energy storage with mechanical strength. Imagine a world where the battery is no longer a bulky component hidden in the floor of an electric vehicle (EV), but instead, it’s part of the vehicle’s frame itself. This innovation promises to make EVs lighter, faster, and more efficient than ever before.

What Are Structural Batteries?

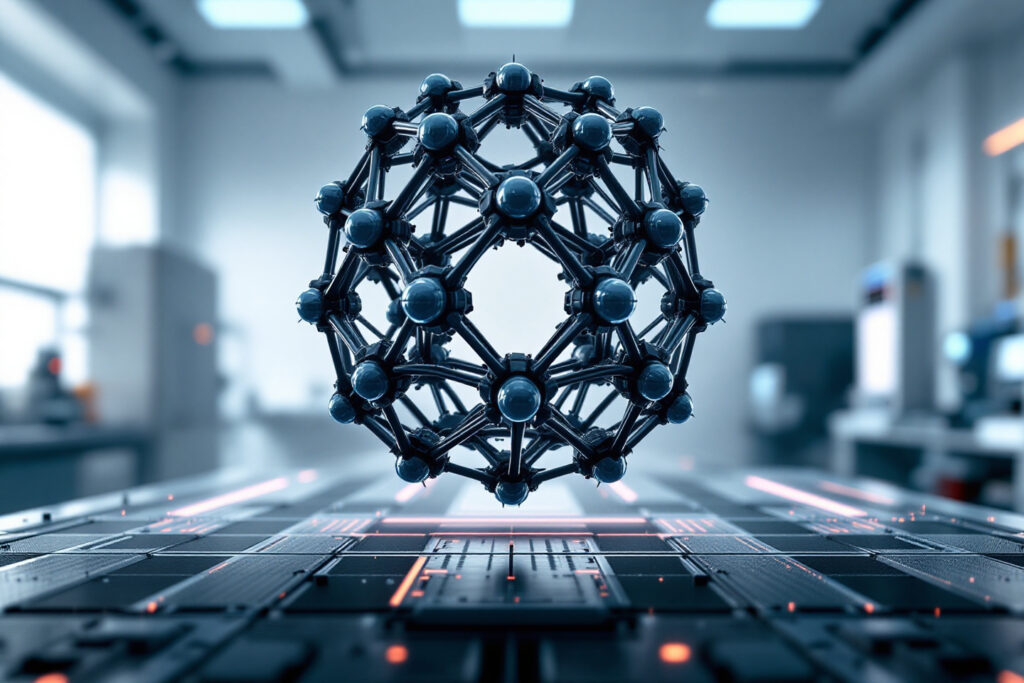

Structural batteries do double duty: they store electrical energy like a regular battery while also bearing mechanical loads, meaning they’re part of the car’s physical structure. This is made possible by carbon fibers, a super-strong and lightweight material already used in high-performance cars, airplanes, and sports equipment.

In this new design, the carbon fibers act as both energy storage and reinforcement material. Some fibers serve as the battery’s negative electrode, while others, coated with lithium iron phosphate (LFP), serve as the positive electrode. These layers are separated by a thin material and embedded in a special electrolyte that allows electricity to flow.

Why Is This a Big Deal?

- Weight Reduction

Electric cars are heavy because of their large batteries. Structural batteries integrate the battery into the car’s body, cutting down on weight. Lighter cars mean less energy is needed to move them, which improves range and performance. - Efficiency Boost

By combining two functions—energy storage and structural support—this battery saves space and materials, making vehicles more efficient and sustainable. - Game-Changing Potential

Structural batteries could reduce vehicle weight by up to 20%. This not only increases driving range but also opens the door to new designs for cars, planes, and even portable electronics.

How Does It Work?

- Carbon Fiber as Electrodes

The carbon fiber acts as the backbone of the battery. One part serves as the negative electrode, while another part coated with LFP becomes the positive electrode. - Thin Separator and Electrolyte

A thin layer keeps the electrodes apart to prevent short circuits. The entire setup is embedded in a special solid-liquid electrolyte, which conducts electricity and provides rigidity. - Durability and Performance

These batteries are tough. They’ve been tested for over 1000 charge cycles with nearly 100% efficiency, and their mechanical strength outperforms other materials with an elastic modulus of 76 GPa (that’s really strong!).

What Does This Mean for You?

For EV owners, it means lighter cars with longer driving ranges. For the planet, it means fewer materials and less waste in manufacturing. And for tech enthusiasts, it’s a glimpse into a future where batteries do more than just store power—they become an integral part of the devices we use.

When Can We Expect This?

While still in the research phase, structural batteries have the potential to appear in commercial vehicles within the next few years. As the technology advances, it’s likely to expand into aerospace, consumer electronics, and other industries.

The carbon fiber structural battery is a step toward a more sustainable and efficient future. By reimagining how we build and power vehicles, this technology has the potential to reshape the transportation industry—and beyond.

R. Chaudhary, J. Xu, Z. Xia, L. E. Asp, Unveiling the Multifunctional Carbon Fiber Structural Battery. Adv. Mater. 2024, 2409725. https://doi.org/10.1002/adma.202409725