A Game-Changing Leap in Battery Technology

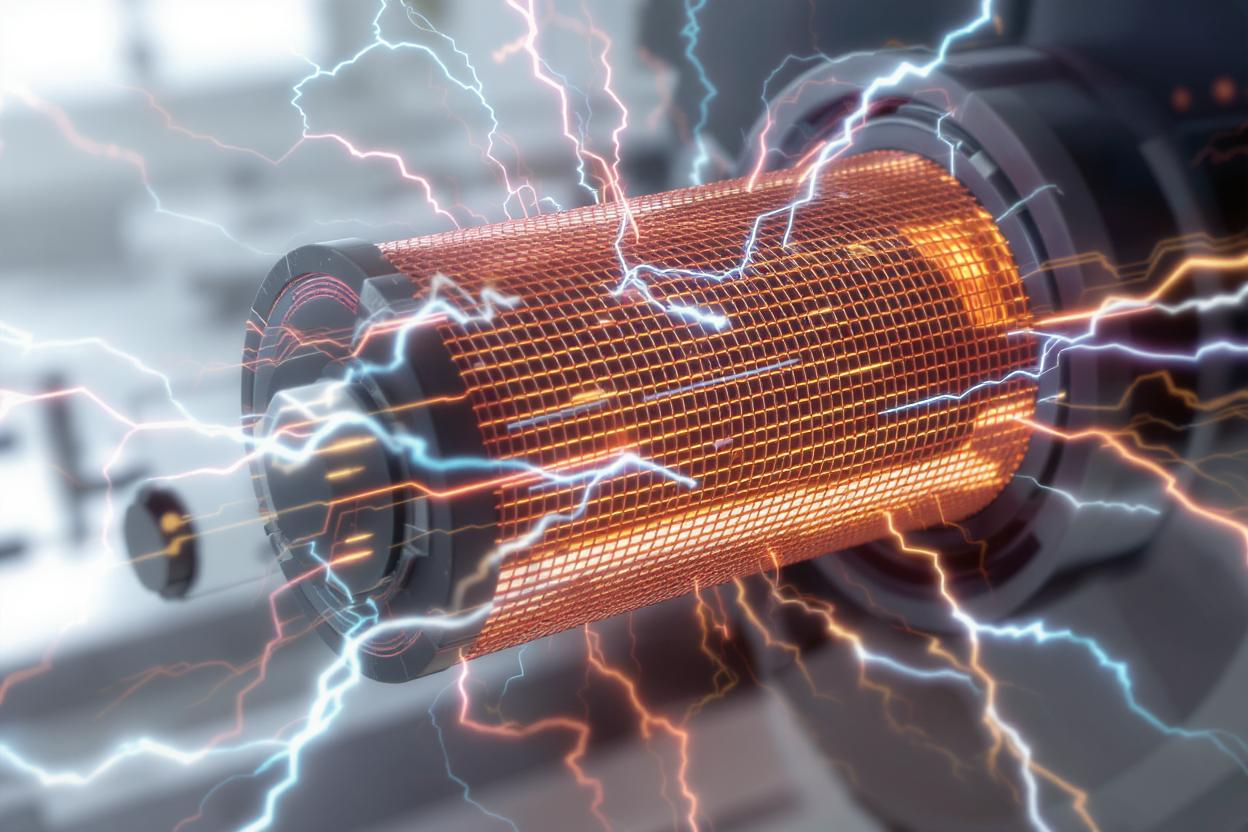

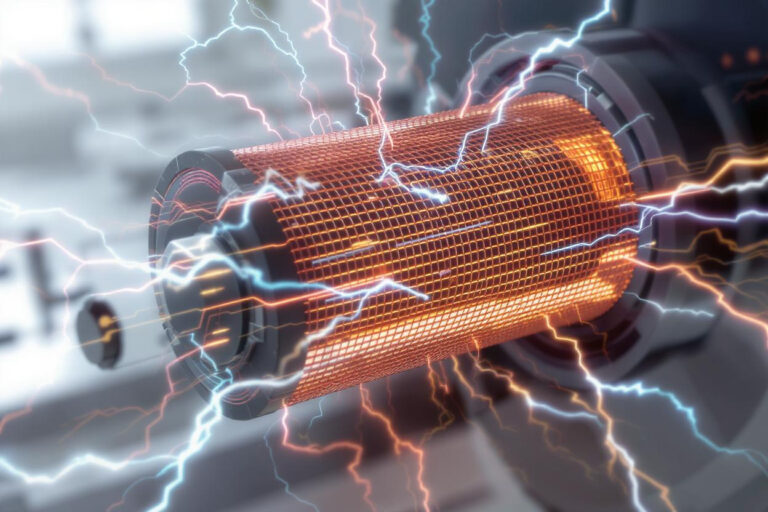

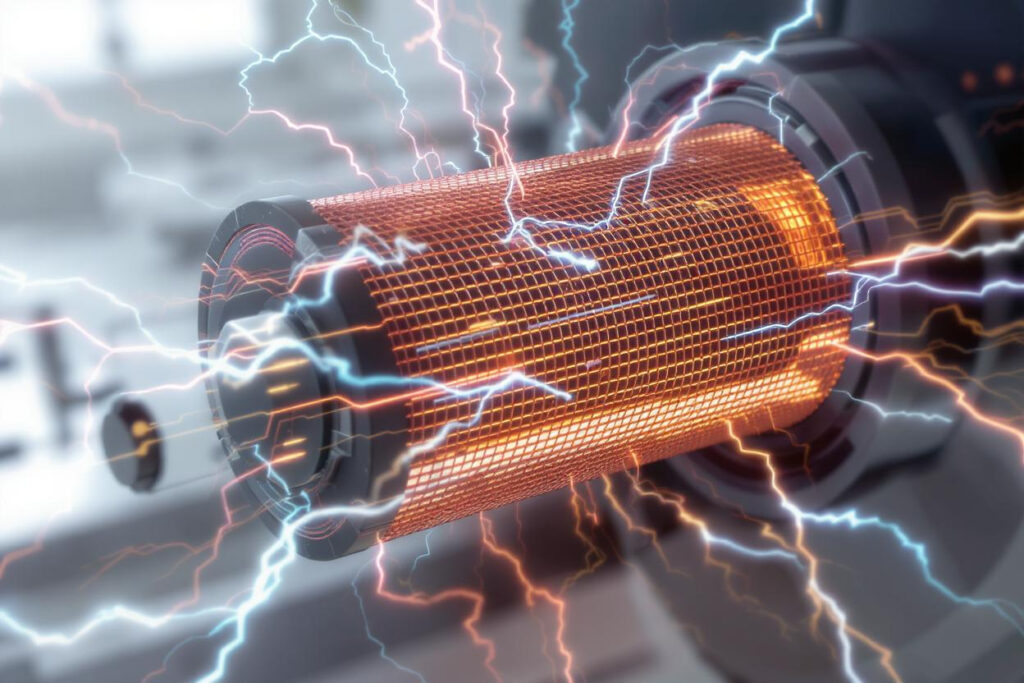

Imagine a battery that charges faster, stores more energy, and costs less to make. Thanks to groundbreaking research by the Max Planck Institute for Medical Research, that future may soon be a reality. Scientists have developed a new type of battery electrode using metal fleece—a mesh of ultra-thin copper fibers—that dramatically enhances battery performance.

This innovation, now being commercialized by Batene GmbH, could reshape the global battery industry, especially in electric vehicles and energy storage.

What Is Metal Fleece?

Unlike traditional battery electrodes made from flat metal foils (usually copper or aluminum), metal fleece is a 3D structure woven from fine metal fibers. Think of it as a microscopic motorway network for lithium ions, allowing them to move significantly faster during charging and discharging.

This fast-track ion transport means that battery electrodes can be up to 10 times thicker than today’s standard designs—without slowing down performance.

Why It Matters: Higher Energy Density & Lower Costs

Here’s why this breakthrough is so exciting:

- 85% higher anode energy density: Thicker electrodes = more storage.

- 40% more energy in the whole battery: More range for EVs, longer battery life for devices.

- Faster charging: Thanks to rapid lithium ion flow along metal surfaces.

- Cheaper manufacturing: Dry-filling metal fleeces with active material saves 30–40% on production costs.

- Smaller production footprint: Factories using this tech need 30% less space.

In short, metal fleece electrodes could lead to cheaper, faster-charging, and longer-lasting batteries.

The Science Behind the Innovation

Lithium ions typically move slowly through the liquid electrolyte and the porous active material inside today’s batteries. That sluggish movement forces manufacturers to keep electrodes thin—like a human hair—to ensure speed.

But researchers discovered that when lithium ions hit a copper fleece, they form an ultra-fast “Helmholtz layer” where they move 56 times faster than through the electrolyte. That’s the secret sauce: rapid transport via surface conduction, not bulk migration.

This allows scientists to embed the active material directly into the fleece and build thicker, more powerful electrodes.

From Lab to Market: Batene GmbH Takes Charge

Realizing the commercial potential, project lead Prof. Joachim Spatz founded Batene GmbH to bring this tech to the global battery market. The company is already working with major automotive manufacturers to implement fleece electrodes in next-gen batteries.

Even better, the process avoids toxic solvents and complex coating steps used in conventional production. It’s cleaner, faster, and cheaper—perfect for scaling up.

As Spatz explains:

“Nature doesn’t transport nutrients in flat sheets—it uses 3D vessels. We’re doing the same for battery charge.”

Why You Should Care

Whether you’re driving an EV, using a smartphone, or powering your home with solar panels—batteries are the backbone of modern energy. Metal fleece technology could:

- Make electric vehicles more affordable

- Extend battery life in electronics

- Boost clean energy adoption with cheaper storage

- Help Europe compete with Asia in battery manufacturing

This isn’t just better battery science—it’s a blueprint for energy independence and sustainable tech.

Check out the cool NewsWade YouTube video about this article!

Article derived from: Metal fleece: material for the batteries of the future. (n.d.). https://www.mpg.de/24758041/material-for-the-batteries-of-the-future