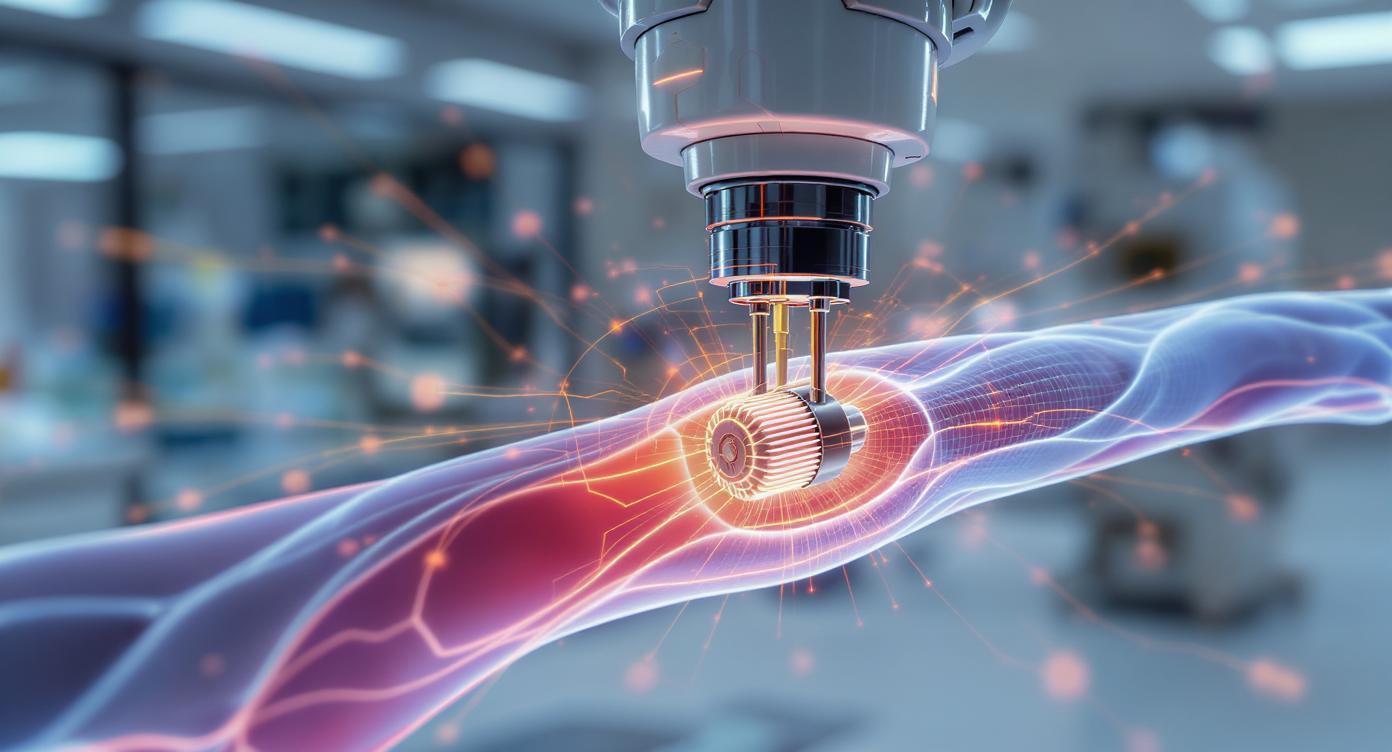

Imagine guiding a microrobot through the body—no MRI, no X-rays, just a tiny motor and one smart sensor.

That’s exactly what scientists have achieved in a new study published in Communications Engineering. The research introduces a novel method of magnetic localization using PMSM (Permanent Magnet Synchronous Motor), offering a promising route toward ultra-precise, image-free navigation of microrobots for medical procedures.

This innovation could dramatically transform how surgeons and researchers operate deep within the human body using microrobots, opening the door to non-invasive diagnostics, targeted drug delivery, and even soft-tissue repair.

What’s New: A Locking Mini Motor That Speaks Magnetically

At the heart of this breakthrough is a millimeter-sized locking motor. It’s equipped with a rotating permanent magnet and a special alloy that melts with heat, allowing the rotor to spin when needed and lock in place for manipulation.

Unlike other systems that require multiple sensors or bulky imaging equipment, this motor can be localized and controlled using just one tri-axial Hall effect sensor. That sensor is mounted on a robot arm, enabling precise tracking and manipulation in 3D.

How It Works: A Symphony of Magnetism and Heat

- Localization Mode: The motor’s rotor spins, generating a rotating magnetic field. A nearby sensor picks up the field’s changing pattern and uses it to calculate the motor’s exact position and orientation.

- Manipulation Mode: Heat melts the locking alloy, allowing the rotor to freeze in place. At this point, external magnetic fields steer the motor like a remote-controlled submarine.

The whole system runs without cameras, radiation, or internal sensors—making it uniquely suited for inside-the-body applications.

Why It’s a Game-Changer

Here’s what makes this breakthrough so exciting:

- Eliminates dependency on fluoroscopy or MRI

No more need for expensive, radiation-based, or bulky imaging tech. - Massive miniaturization potential

The motor is smaller than a grain of rice. Perfect for microsurgery. - Dual-purpose coils

The same coils that power the motor also provide heat to unlock the rotor—simplifying the design. - Eye-in-hand sensor system

A robotic arm with a built-in sensor tracks the motor’s every move, allowing closed-loop control.

Real-World Potential: From Veins to Robots

This technology isn’t just a proof of concept—it has wide-reaching potential:

- Intravascular surgeries

Navigate through arteries and veins without harming tissue. - Implantable actuators

Control devices inside the body with pinpoint precision. - Magnetic microrobots

Power tiny swimming robots with better feedback and control. - Wireless energy & therapy

Possibly aid in wireless charging of implants or local magnetic field therapies for nerves or cancer cells.

How Accurate Is It?

Tests showed:

- Position error within 7 mm.

- Angular error as low as 5–15 degrees.

- Localization frequency of 0.3 Hz, with potential to scale up to 10 Hz.

- Working range of up to 40 mm from the sensor—extendable with better sensors.

That’s impressive for something running with just one sensor and no camera.

What’s Next?

Future improvements may include:

- Triangulation with multiple sensors for even better accuracy.

- Faster rotor speeds and localization for real-time control.

- Medical-grade encapsulation to make it biocompatible and implant-ready.

- Simultaneous multi-motor tracking using signal frequencies.

As sensors improve and motors shrink, the dream of deploying intelligent micro-devices inside the human body is fast becoming a reality.

Check out the cool NewsWade YouTube video about this article!

Article derived from: Richter, M., Masjosthusmann, L., Makushko, P., Venkiteswaran, V. K., Makarov, D., & Misra, S. (2025). Magnetic localization and manipulation of locking synchronous motors. Communications Engineering, 4(91). https://doi.org/10.1038/s44172-025-00206-2