Introduction: Why Rocket Science is Getting Sticky

Imagine rockets powered by 3D-printed fuel that can take us further, faster, and for less cost. Sounds futuristic, right? Well, the future is here, and it’s sticky! Scientists have discovered how the gooey material polybutadiene, a type of synthetic rubber, can revolutionize the way we make rocket propellants. And guess what? The magic lies in how tiny droplets of this material spread on surfaces—kind of like how pancake batter spreads on a griddle!

Let’s break it down and make it fun to understand how this works and why it’s such a big deal.

The Problem with Rocket Fuel (And How 3D Printing Could Fix It)

Most rockets today use traditional manufacturing methods for their solid propellants—fancy words for the stuff that makes rockets go “boom” and zoom. But these methods are clunky and expensive. When we want fuel shapes that are super precise (like for high-thrust missions), traditional techniques don’t cut it. Enter 3D printing, which allows engineers to craft complex fuel designs layer by layer.

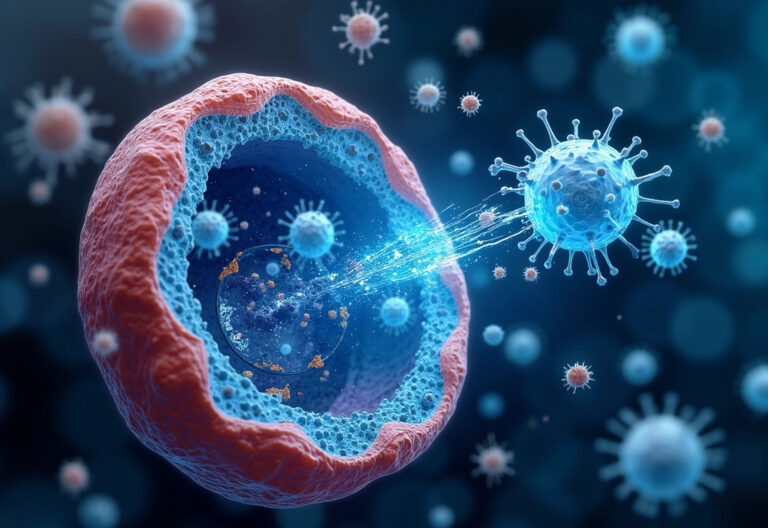

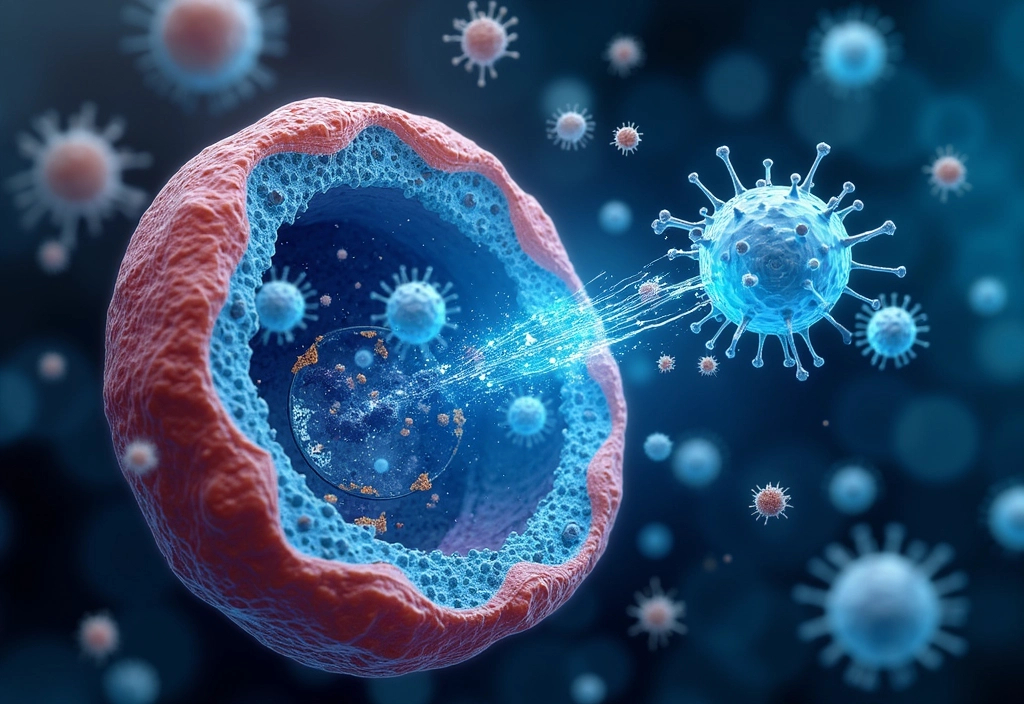

But there’s a catch. To make this work, the liquid binder (like polybutadiene) has to behave in just the right way when it lands on the surface of powdered fuel. It needs to spread smoothly, stick where it’s supposed to, and not splash everywhere. That’s where this groundbreaking study comes in.

The Science of Goo: How Droplets Spread

Picture this: A droplet of polybutadiene falls from a tiny nozzle onto a bed of powdered rocket fuel. What happens next?

- The Drop Lands with a Splat!

Just like jumping into a pool, the droplet starts spreading. At first, it’s all about inertia (think of how cannonballs create big splashes). - Slowing Down (Thanks to Viscosity):

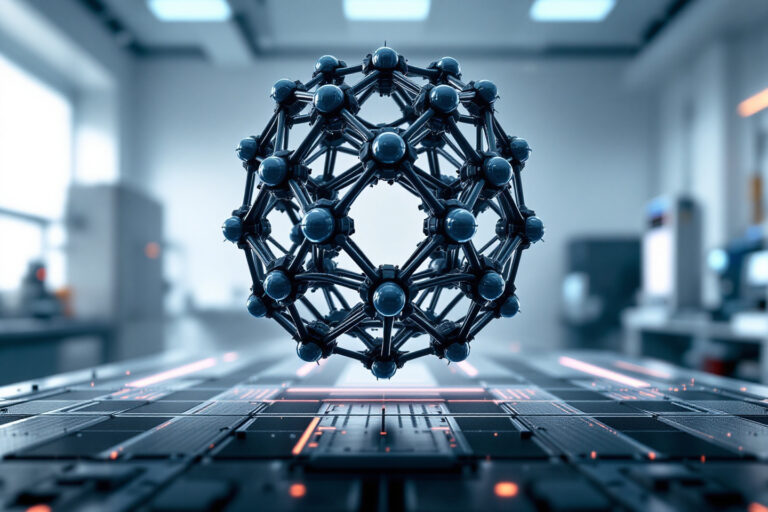

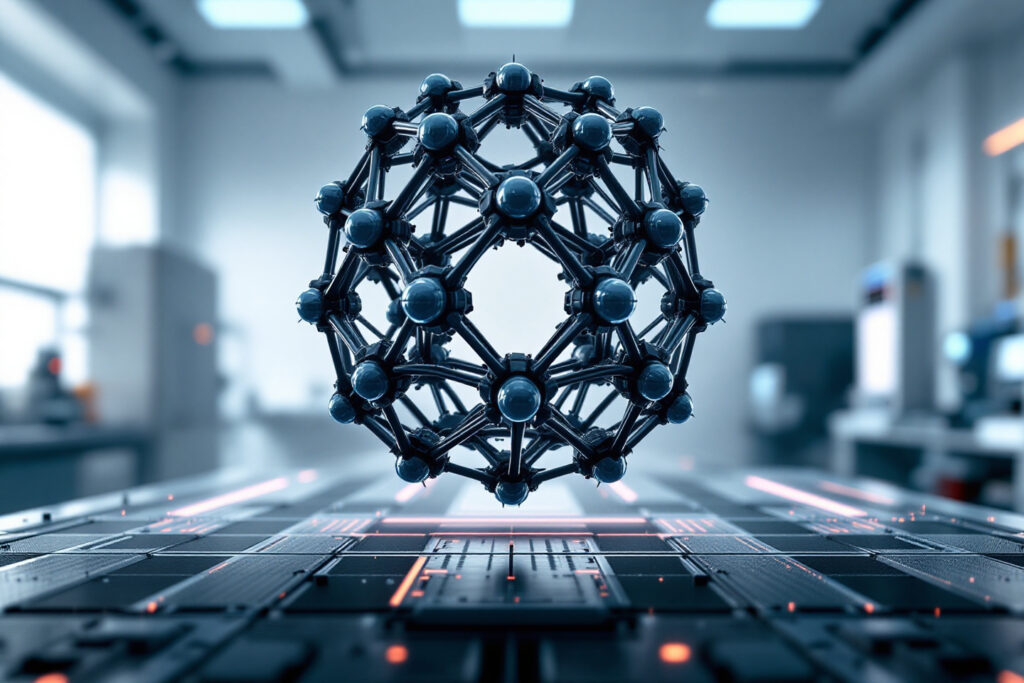

As the droplet spreads, its gooeyness—or viscosity—takes over. Depending on the droplet’s structure (linear or branched), it either spreads smoothly or stays more clumped up. - Branched vs. Linear Goo:

The coolest part? Branched polybutadiene spreads up to 25% more than its linear cousin. Even though branched goo is thicker, it forms a better bond with the surface because its structure allows more sticky points to grip the powdered fuel.

Why This Matters for Rocket Science

Here’s where it gets exciting: The way a droplet spreads directly affects the final product. Better spreading means:

- Sharper Designs: Perfectly shaped fuel layers that burn more efficiently.

- Stronger Bonds: Improved adhesion between the binder and the fuel particles for better performance.

- Smaller Rockets, Bigger Power: High-precision designs mean we can pack more punch into smaller rockets.

By understanding how to tweak the droplet structure, scientists are unlocking a new level of control over how fuel is made, making rockets more powerful and missions more affordable.

Explaining It Like You’re in Chemistry Class

Okay, imagine your school’s science fair. You’ve got a project with slime—one kind stretches a lot, while the other sticks better. That’s what’s happening here, but with rocket fuel. Scientists are testing different types of slime (polybutadiene) to see which one works best when squished onto powdered rocket fuel. The one that spreads wider and sticks better wins!

What This Means for You and the Future

This isn’t just about rockets; it’s about 3D printing taking over industries like never before. If we can print something as complex as rocket fuel, think about the possibilities: custom medicines, sustainable buildings, even on-demand food in space!

Plus, this technology could inspire the next generation of inventors (hey, that could be you!) to dream up new ways to use gooey science for solving problems.

Final Thoughts: Science is Goo-d for the Future

Polybutadiene might not sound as cool as Iron Man’s suit, but it’s making real-life rocket science a whole lot cooler. With its sticky, stretchy magic, we’re printing the future—one droplet at a time.

So next time you hear someone say, “It’s not rocket science,” you can tell them, “Actually, it is!”

Article derived from: Raissi, S.D., Magaña, M.A., Contreras, A. et al. Polybutadiene structural effects on dynamic wetting. npj Adv. Manuf. 1, 7 (2024). https://doi.org/10.1038/s44334-024-00007-8

Check out the cool NewsWade YouTube video about this article!